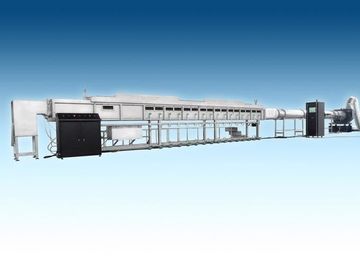

Flammability Testing Equipment Flame travel and smoke of wires and cables testing equipment NFPA262

Introduction:

The UL910/NFPA262 steiner tunnel furnace shall prescribe the methodology to measure flame travel distance and optical density of smoke for insulated, jacketed,or both,electrical wires and cables and optical fiber cables that are to be installed in plenums and other spaces used to transport environmental air without being enclosed in raceways.

Standards:

UL910: Test Method for Fire and Smoke Characteristics of Electrical and Optical-Fiber Cables Used in Air Handing Spaces

NFPA262: Standard Method of Test for Flame Travel and Smoke of Wires and Cables for use in Air-handing Spaces

Fire Tesr Apparatus:

- Air-inlet chamber

- Air-inlet shutter

- Gas burner

- Fire test chamber

- Removable top cover

- Exhaust transition

- Exhaust duct

- Exhaust duct velocity measurement system

- Smoke measurement system

- Exhaust duct damper

Installation requirements:

| Electrical |

AC 380V, 50/60hz, 30A |

| Ambient Temperature |

Operating 15°C to 35°C |

| Gas |

Methane and air compressor |

| Utility |

Crane |

| Size |

1300 mm (L) x 1100 mm (D) x 2100 mm (H) |

| Weight |

1700KG |

| Applicable standards |

UL910,NFPA262,ASTM E84,UL723 |

Technical parameters:

1. The combustion chamber is made of stainless steel, with firebrick laid inside.Good insulation.The inner dimensions of the combustion chamber are 305mm x 451mm and 7.6m long.

2. The internal tools and fixtures are made of SUS304 stainless steel, rust and corrosion resistant.

3. Double-layer quartz glass observation window can observe the flame spread distance, and display the flame advance position through the indicator light, which makes the recording more intuitive.

4. The height of the combustion chamber is suitable for people to watch the combustion state and install, and adjust the sample;

5. The combustion box cover is designed as a whole, and the tank seal is designed according to the standard. The tank is equipped with the stainless steel water seal of 2mm thick to ensure that the smoke will not leak during the test.

6. The box cover is made of refractory materials and stainless steel. The box cover is equipped with a hook and a hoisting cover device.

7. The sample holder is equipped with cooling water circulation support bracket, which is resistant to high temperature and can support combustion coverings such as calcium silicate plate.

8. SUS304 stainless steel upper cover of the insulation body, filled with heat-resistant insulation materials

9. Provide escalator-type sample installation platform for easy installation, installation and removal of samples and overhaul of furnace tube;

10. Stainless steel smoke exhaust pipe, beautiful and corrosion-resistant;

11. Independent and multi-functional exhaust pressure testing device: real-time monitoring of exhaust pressure changes during testing.Test range: 0 ~ 250Pa; accuracy: 0.5pa; system pressure:±2Pa

12. Fan: 380V, 50Hz and 3Kw are equipped with frequency converter to change the wind speed.The maximum flow rate shall be at least 8000m3/h, which can timely discharge the flue gas generated under the severe combustion of the sample out of the room to ensure the safety of the test;

13. Dual-head copper gas burner: the burner is 1320mm away from the air inlet, and can output the heat of the standard 5.3mj /min. The gas flow can be controlled by the mass flowmeter according to different standards.

14. Automatic ignition system: ensure the safety performance of the test, high-pressure ignition, 12KV, 50mA, and the minimum high pressure of ignition electrode is 1.8kvp;

15. Smoke density system: a separate signal processing system is provided to ensure that the sensor is linear;

16. Automatic recording of temperature and flue gas sensor signals, sample acquisition frequency of 1Hz;

17. Mass flow controller:SUS316 stainless steel material, the maximum pressure of 1000 psi (70 bar), the leakage rate is less than 1 x 10-7 ml/s, the NIST calibration, 0 ~ 5 VDC and 4 ~ 20 ma signal, circuit protection, propane flow range 0 ~ 2.3 g/s, 2 s or less control speed, the range of 0.6 ~ 2.3 g/s control accuracy of plus or minus 1% FS, repetitive ± 0.5 FS, temperature range of 0 ~ 50 ºC, humidity range of 0 ~ 90%, digital display, automatic control test in the process of gas supply to meet 5000 btu (MJ) 5.3 / min quantity of heat,The software automatically records the amount of gas used;

18. Standard test software can automatically record the wind speed, temperature, smoke density and other test data of the system.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!