DX8635A Insulation Material Heat Loss Measurement Instrument

I. Overview:

In order to meet the requirements of production processes and energy conservation, improve working conditions, enhance economic benefits, and ensure the quality of insulation engineering design, GB 50264-2013 specifies the design of pump equipment.

This equipment is applicable for measuring the heat loss of insulation materials on the outer surfaces of industrial equipment and pipelines with temperatures ranging from -196℃ to 850℃.

It is not applicable to equipment and pipelines with special requirements in nuclear energy, aerospace systems, as well as in buildings, cold storage facilities, and buried pipelines.

Instrument reference standard:

GBT 10294-2008 Determination of steady-state thermal resistance and related properties of insulation materials - Protective heat plate method;

GB 50264-2013 Design Code for Insulation Engineering of Industrial Equipment and Pipelines.

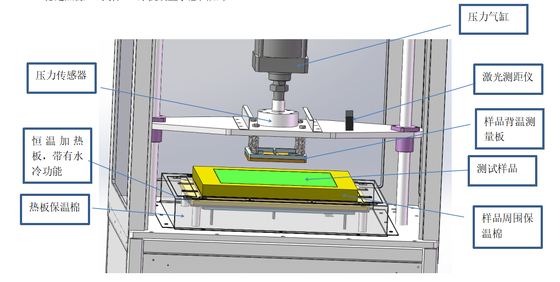

II. Overall structure of the equipment

The equipment is mainly composed of temperature control system, cylinder pressurization system, thickness measurement system, cooling system, etc. The overall structure of the equipment is as shown in the following figure, and the control interface is as follows:

Overall structure of the equipment

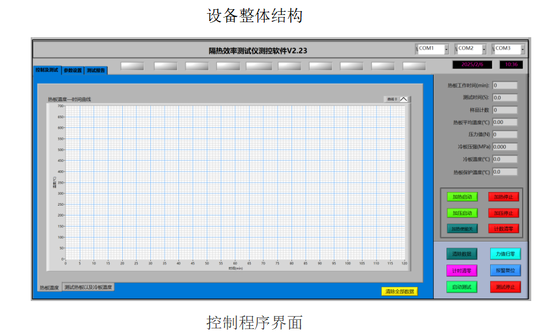

Control Program Interface

2.1 Temperature Control System

It is mainly composed of heating wires and iron plates, and is controlled by a temperature meter. The heating capacity of the temperature zone can reach up to 600 degrees Celsius, and the long-term usage temperature can reach 500 degrees Celsius. A total of 12 temperature collection channels are equipped, among which the heating temperature channel is for closed-loop control of the temperature zone, and there are 5 temperature monitoring points. The remaining heat protection plates have 2 temperature monitoring points, and the cold surface is arranged with 5 temperature measurement points.

2.2 Pressurization System

It mainly consists of cylinder pressurization, and the required pressure value is achieved through fine adjustment of the air pressure, and the current status is displayed in real time in the control system.

2.3 Cooling System

It is mainly composed of water chillers and thermocouples. The water chiller cools the heating part of the equipment, and the thermocouple detects the bottom surface temperature. After the test, when the bottom surface temperature is >50℃, it prompts "Start water chiller" and quickly cools the hot plate.

Control Interface 2

2.4 Working Principle

2.4.1 The equipment is composed of a sample back temperature measurement board, a constant temperature heating board, and a pressurization system. The sample back temperature measurement board is equipped with 5 temperature sensors, which measure the temperature of the sample's back surface in real time. The constant temperature heating board provides a stable high-temperature heat source, and the pressurization system provides stable pressure to the sample to ensure the reliability of the test.

2.4.2 The equipment has two functions: measurement of thermal conductivity and measurement of heat loss. First, the thermal conductivity is tested, then the heat loss is tested; both are completed at the same workstation.

2.4.3 Calculating heat loss:

Calculate the heat loss according to Standard GB 50264-2013, Clause 5.4.

The system is based on the principle of stable heat conduction. A stable heat source is added to one side of the sample to form the temperature of the hot surface. The sample surface is pressurized through the cylinder pressurization system. Under the set temperature and pressure, the heat from the hot surface is transferred to the cold surface. The temperatures at different test points on the cold and hot surfaces are measured and recorded by the cold plate thermocouple, and the computer is used to achieve automatic detection, generating an experimental report.

The schematic diagram of the placement of the stable heat source, the sample, and the cold plate is as follows:

Equipment sample placement diagram

The temperature control system uses a multi-zone heating wire method for heating, ensuring uniform temperature on the heating plate and good heating stability, with high temperature control accuracy. The heating plate is made of high-temperature-resistant alloy metal material, with good thermal conductivity, low thermal expansion rate, and high compressive strength at high temperatures, meeting the requirements for the equipment to be used for a long time at 500°C.

The pressurization system uses a cylinder to drive the cold plate for pressurization. The cylinder uses a servo pressure stabilizing control valve to control the pressure, outputting a constant pressure, and simultaneously adjusting the pressure flexibly through a spring, thereby achieving the purpose of controlling the pressurization accuracy.

The system is controlled by a computer, and the test can be started with a single click. After the test, an automatic report is output. The automation level is high; in combination with the dedicated measurement and control software, the test progress is high, the operation is stable, and the test efficiency is high.

II. System operation

3.1 Connect the system power supply

(1) Open the main power switch on the equipment and the refrigeration machine power switch

(2) Open the computer power switch, wait for the self-check to start.

(3) Double-click the icon of the heat loss measurement software on the desktop to enter the system operation interface.

3.2 Parameter setting

Enter the target heating temperature, pressurization target pressure value, test time, etc. in the setting column, and click the write button;

3.3 Start the test

Press the start button to add, prompt whether to test the material thermal conductivity first. Click yes to start testing the material thermal conductivity, then test the material heat loss amount. If no, directly start heating to test the material heat loss amount, wait for the temperature to rise to the target temperature and stabilize, start collecting data and calculating the heat loss amount, just wait for the test results;

3.4 Test start

Click the test button to start the test. The system automatically pressurizes and starts the test. No human intervention is required in the middle. Just wait for the test to be completed;

3.5 Output report after test

After the test is completed, an Excel file report is automatically output;

The content includes temperature curves and one-second interval collected data, material thermal conductivity, material applied pressure value curve and data, final material heat loss rate;

3.6 Test completion

Test completion. Turn on the cooling system, wait for the heating plate temperature to drop to room temperature, close the software, then turn off the power.

IV. Main Technical Parameters:

1. Overall size approximately: Length 800 * Width 850 * Height 1200 (mm) (excluding the size of the water chiller)

2. Total weight approximately: 160KG

3. Rated voltage: AC 220V

4. Total power: ≤ 5.0kW

5. Heating power ≤ 4.5kW

6. Heating is achieved through multi-point constant temperature control to ensure the uniformity of the heating plate temperature;

7. Water chiller:

Uses imported compressors from France, with long service life and stable operation. The temperature controller uses Omron, with precise temperature control. The thermocouple uses PT100 high-precision temperature sensors, with an accuracy of ±0.15℃ and a temperature uniformity of 0.2℃. Total power: 1.8KW

8. Heating plate: The heating plate is made of copper, and heating is achieved through multi-point constant temperature control to ensure the uniformity of the heating plate temperature. The temperature uniformity is within 0.5℃; the maximum heating temperature: 600℃

9. Fastest heating rate: 20℃/min

10. Temperature control accuracy: ≤ 0.5%FS (within the range of 300*300mm of the heating plate center)

11. Heating plate temperature sensor: Uses imported high-precision temperature sensor PT100, with an accuracy of ±0.15℃

12. Heating plate temperature controller: Uses high-precision temperature controller from Yu Electric, with high control accuracy and stable output

13. Force sensor: Uses Japanese MANTON wheel-type pressure sensor fourteen Thickness measurement: Uses Keyence laser high-precision distance measuring instrument, with a measurement range of 0 - 80mm. Test accuracy: ±0.05mm;

15. Sample size: Maximum 300*300mm

16. Hot plate size: 370*370mm; Cold plate: 300*300mm (2 pieces, easy to replace)

17. Maximum loading pressure: 5000N

18. Maximum loading pressure: 1MPa (equipped with one 300w compressor)

19. The computer uses Taiwan Industrial Control Computer from Rockwell, with CPU i5 10th generation, 8GB memory, 256GB solid state drive, and a Samsung 23-inch monitor.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!