Part 1: An overview of the system components and their uses

The system consists of the following components :

The function of the test chamber is to provide a test environment such as high and low temperature constant, high and low temperature alternating;

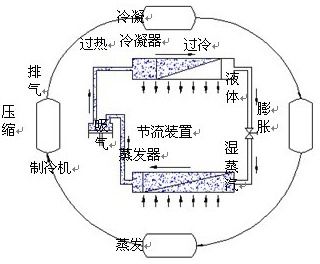

It is composed of refrigeration system, heating system, air duct system, control system, system safety protection device, etc

Part 2: The main technical indicators of the test chamber

Workroom size 500×500×600mm(deep × width×height)

Dimensions 970×1050×1750mm (deep × width×height)

Temperature range -0℃ ~ +150℃ (When there is no load and is in a constant state)

Temperature fluctuation ≤±0.5℃ (When there is no load and is in a constant state)

Temperature uniformity ≤1℃ (When there is no load and is in a constant state)

Cooling rate From room temperature to 150°C, about 45 minutes (20°C~100°C range, no load, the whole process of nonlinear heating)

Wind speed 1.7 ~ 2.5m/s

The above indexes were measured at ambient temperature ≤25°C, atmospheric pressure, no-load, no-load conditions, and 1/6 space from the inner wall of the box

Power Approx. 4.5Kw

Airflow velocity range 0.02~3m/s

Power supply 220V±10%V;50Hz

Moisture permeable area 3000mm2 (ASTME96 standard) 6pcs

Humidification capacity ≥250mL/h

Humidity range 20%~98%R.H(AT+25℃~+85℃)98%RH (There is no heat source during the damp heat test)

14.Humidity error:≤+2~-3.0%RH (humidity >75%RH) (at constant state)

≤±5.0%RH (humidity ≤75%RH) (at constant state)

15. Meet the relevant standards and test methods MIL-STD-2164/(E/C),GB/T12704,ASTME96,JIS L1099,GB/T2423.4-93, GB/T2423.34-86 ,GJB150.9-86

Main unit and accessories and testing software:

Product Certificate 1pc

Instruction manual for the product 1set

Warranty card 1set

Thermometer 1

Power cord 1

Part 3: Description of the design and manufacturing scheme of the programmable fabric moisture permeability test chamber

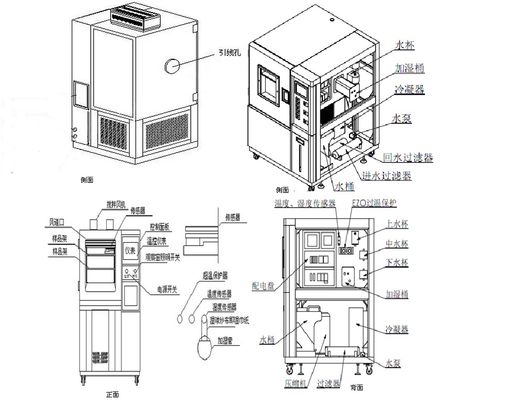

Structural form: That is, the test chamber, the refrigeration system, the air conditioning system, the electrical control cabinet and the refrigeration unit are a whole, the refrigeration unit is located at the bottom of the box, and the electrical control part is placed on the side of the test chamber for easy operation

Workroom: Distributed heaters, refrigeration evaporators, blower motors, fan blades, air ducts and other devices

Test holes: The side of the test chamber is equipped with 1 cable threading hole, and the size is 50mm

Inner box material: Made of 1mm thick SUS304 mirror stainless steel plate, high-end

Outer box material :1mm thick high quality brushed stainless steel plate manufactured. Easy to clean and have long lifetime

Insulation material: The insulation material is made of polyurethane foam, with a thickness of 100mm, the thermal insulation effect is good, and the outer surface of the test chamber does not frost or condensation

Inner box configuration: The workroom is equipped with a height-adjustable stainless steel strip shelf

Drain: The box is equipped with a condensate drain

The bottom of the box: Set up a water outlet at the bottom to let the liquid in the box flow out freely and smoothly, that is, the liquid can not accumulate at the bottom of the box, there is a water tank under the box with a water table, the water tank is filled with distilled water, pure water, bottled water should not be connected to the tap water or will be blocked by the substances in the tap water

Door: Single-door design, using silicone rubber sealing strip, high and low temperature resistance, anti-aging, good sealing performance. In order to prevent condensation or frost on the edge of the door frame and door during the low temperature test, the edge of the door frame and door is provided with an electric defrosting device, and the hardware accessories such as door locks and hinges are "KUNLONG" original accessories

Door handles: It adopts buckle and pull structure, single opening, left hinge, right handle, lever power opening, convenient and easy switching, beautiful and generous

Observation window: The door of the test chamber is equipped with a 400×500 mm (width × height) hollow resistive film heating and frost protection observation window, and is equipped with an anti-ultraviolet observation window cover and a heating and frost protection device. Installed on the door of the test chamber

Inspection lights: The observation window is equipped with a (AC12V) 20W halogen lamp with a long-life controlled observation light source

Mobile devices: Four movable casters can be fixed

Positioning leveling device:Ensure that the test chamber can work smoothly

Main unit and accessories and testing software:

Product Certificate 1pc

Instruction manual for the product 1set

Warranty card 1set

Thermometer 1

Power cord 1

Conditions of use of the device

Humidify with water:Purified water, distilled water, deionized water, resistivity ≥ 500.m

Cooling method: Air cooling method: ambient temperature +5~+28°C is the best

Voltage: AC 220V±10%, 50 Hz, three-phase four-wire + ground wire

Ambient temperature:0~40℃

Ambient humidity: < 85%R.H

Atmospheric pressure :86~106Kpa.

Site Requirements: The equipment should be placed horizontally in a well-ventilated test room, with sufficient space around it for operation and maintenance

Spatial conditions:The test chamber should be at least 200mm away from the room around the room, and the equipment should be open and closed normally

Environmental conditions: There is no strong vibration, no strong electromagnetic field interference, no high concentration of dust and corrosive substances, no direct sunlight or other direct radiation from heat sources around the equipment site

Frequency and error: 50±0.5Hz

Voltage and error: AC 220V±10%V

Master switch :A separate space is required

Details of the core components

Control panel

TEMI850 controller features

1. Color touch screen

2. Two control modes (fixed value/program)

3. Sensor type: PT100 sensor

4. Output mode: PID control output; (4-20mA) analog output;

(1-5V)/(0-10V) can be arbitrarily selected, 8 switch signal auxiliary input; (Basic configuration of 10 relays, optional 20 relays) ON/OFF relay output;

5. Temperature measurement range: -90.00°C--200.00°C, (optional -90.00°C--300.00°C) error ±0.2°C;

6. Humidity measurement range: 1.0%--100%RH, error ±1%RH;

7. Measurement range: can be set arbitrarily, and special functions can be customized;

8. Program editing: 12 groups of programs can be programmed, and each group of programs can be programmed up to 10 segments, and can be set to run in cycles;

9. Communication interface: (RS232/RS485, the longest communication distance is 1.2km [optical fiber can reach 30km]);

10. Interface language color touch screen language type: Chinese/English

11. TFT resolution: 800×480 64K color

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!